PCBA Manufacturing Services, Contract PCB Assembly Manufacturer

When people talk about advanced electronic products today, they are almost always referring to devices powered by PCBA—the heart of every smart device. PCBA (Printed Circuit Board Assembly) refers to the complete board after electronic components are soldered on a PCB, enabling real functionality. From smartphones and medical devices to automotive controls and industrial automation, PCBA determines stability, reliability, and performance.

In simple terms:

PCB is the empty board, while PCBA is the functioning electronic core.

Without a reliable PCBA, electronic designs remain only concepts on paper.

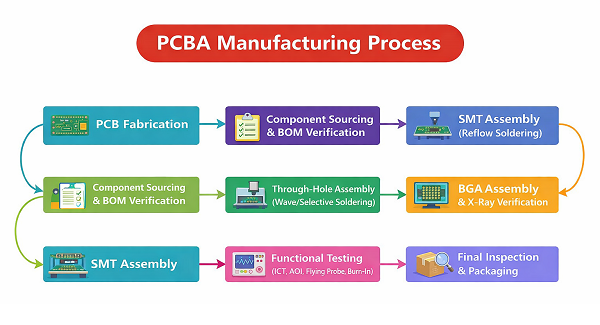

How the PCBA Manufacturing Process Works?

The manufacturing of a professional PCBA product is an engineered, multi-stage process. Each phase contributes directly to the electrical performance and structural stability of the final product. Understanding the workflow helps engineers and buyers communicate better with manufacturers, avoid preventable issues, and control costs more effectively. Below is a complete, end-to-end process:

1. PCB Fabrication

Before assembly begins, the PCB must be fabricated with exact copper routing, dielectric spacing, solder mask thickness, and via structures. The quality of PCB fabrication significantly influences solderability and impedance behavior.

2. BOM Verification and Component Sourcing

The Bill of Materials (BOM) lists every component required for the PCBA. This step ensures:

- Package compatibility

- Correct voltage/power tolerance

- Genuine component sourcing

- Lifecycle availability (preventing EOL risks)

Professional PCBA companies avoid counterfeit parts through authorized distributors and rigorous incoming inspections.

3. SMT Assembly (Surface Mount Technology)

SMT is the dominant approach for modern electronics. It involves:

- Automated solder paste printing

- High-speed pick-and-place machines

- Reflow soldering under controlled temperature profiles

This allows for high component density, fast production, and excellent repeatability.

4. Through-Hole Assembly (THT)

Certain components—like connectors, inductors, power modules—require strong mechanical attachment. THT processes include:

- Wave soldering

- Manual or selective soldering

- Post-reflow assembly

5. BGA Assembly and X-Ray Inspection

Ball Grid Array packages offer strong electrical performance but cannot be visually inspected. X-ray evaluation ensures:

- Proper solder ball shape

- No bridging

- Minimal voids

- Correct alignment

6. Electrical Testing

To ensure the assembly functions as intended, professional PCBA manufacturers use:

- AOI

- Flying probe

- ICT

- Functional testing

- Burn-in testing for reliability

7. Final Inspection and Packaging

After passing all inspections, boards are cleaned, labeled, packed, and ready for shipment.

A well-executed PCBA process is the difference between a stable product and a long list of field failures.

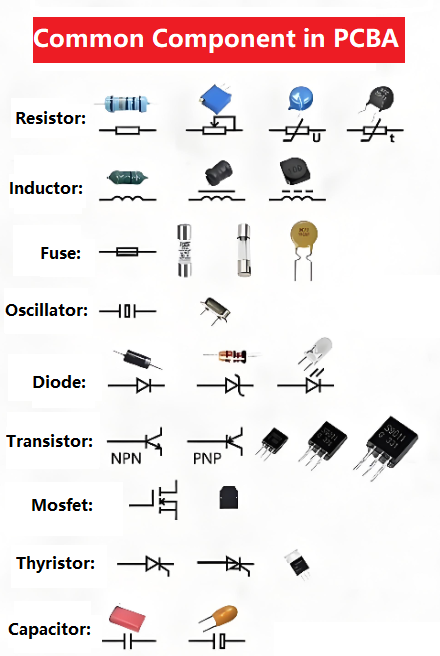

What Components Are Used in PCBA and Why They Matter?

The reliability of a PCBA depends heavily on the quality and suitability of its components. Each part plays a distinct role in how a device behaves:

- Resistors define current control and voltage division.

- Capacitors stabilize power lines and filter noise.

- ICs and MCUs perform logic, computing, and control.

- Power components manage conversion and heat dissipation.

- Sensors enable environmental interaction.

- Connectors define mechanical stability and signal integrity.

Even the smallest deviations—incorrect tolerance, counterfeit ICs, poor solderability—can cause intermittent failures, heat buildup, or early aging.

This is why engineers emphasize high-quality component sourcing from verified suppliers, along with traceable quality control documentation.

SMT vs Through-Hole in PCBA: What’s the Difference

SMT is the most widely used assembly method today. In this process, electronic components—known as SMD (Surface Mount Devices)—are placed directly onto the surface of the PCB. These components do not require drilled holes; instead, tiny metal pads and solder paste are used to secure them in place.

Through-Hole Technology is an older but essential assembly method where component leads pass through drilled holes in the PCB and are soldered on the opposite side. Typical through-hole components include connectors, power inductors, transformers, relays, large capacitors, and mechanical switches.

Key Differences Between SMT and Through-Hole Technology

| Feature | SMT | Through-Hole Technology |

| Mounting Method | Components placed on PCB surface | Leads inserted into drilled holes |

| Automation Level | Highly automated (pick-and-place + reflow) | Partially automated or manual |

| Component Size | Very small (01005, 0201, etc.) | Larger, bulkier components |

| Mechanical Strength | Moderate | Very high |

| Electrical Performance | Excellent for high-speed, RF, and dense routing | Good for power or vibration-heavy applications |

| Typical Use Cases | Consumer electronics, IoT, medical, automotive control systems | Power electronics, connectors, industrial machines |

| Cost Efficiency | Lower cost for mass production | Higher cost due to drilling and manual labor |

SMT is ideal for high-density, high-speed, miniaturized electronics, while Through-Hole Technology is preferred for high-power, high-stress, or mechanically demanding environments.

Common PCBA Technologies Used Today

The demand for smaller, faster, and more powerful devices has pushed PCBA technologies to evolve. Some common categories include:

- HDI PCBA – microvias, fine lines for compact electronics

- Rigid-Flex PCBA – combined flexibility and robustness

- Ceramic PCBA – extreme heat resistance for LEDs and lasers

- Metal-Core PCBA – improved heat spreading for power electronics

- High-Frequency PCBA – RF, 5G, radar applications

- Prototype PCBA – fast iteration cycles for R&D

- Quick Turn PCBA Services – urgent delivery within days

Each technology targets specific industry challenges—whether thermal, mechanical, or electrical.

How to Evaluate a Professional PCBA Manufacturer?

A reliable PCBA manufacturer should offer more than basic assembly. Engineers and procurement teams often evaluate partners using these criteria:

1. Technical Capability

How well can they handle advanced features—BGA, microvias, HDI, rigid-flex?

2. Factory Certifications

Important benchmarks include:

- ISO9001

- ISO13485 for medical

- IATF16949 for automotive

- UL safety requirements

3. Engineering Support

DFM (Design for Manufacturability) reviews reduce costly revisions and improve product stability.

4. Component Sourcing Reliability

Manufacturers must avoid grey-market sourcing and provide traceability.

5. Testing and Inspection

Strong testing frameworks ensure stable production in mass quantities.

6. Lead Time and Flexibility

Fast responses, quick turn production, and flexible scheduling matter greatly for product launches.

Choosing the right partner can reduce risks, accelerate development, and improve long-term product reliability.

What Affects the Cost of PCBA? Key Pricing Factors You Should Know

PCBA cost varies widely based on several main elements:

1. PCB Specifications

Layers, thickness, materials (FR4, ceramic, aluminum, PTFE), copper weight.

2. Components

Availability, package type, brand, and global supply chain conditions.

3. Assembly Complexity

BGA density, double-sided SMT, special soldering requirements.

4. Testing Requirements

More testing equals higher reliability but higher cost.

5. Order Quantity

Prototypes cost more per unit; mass production reduces overhead.

6. Lead Time

Urgent orders require additional labor shifts and setup adjustments.

Transparent pricing helps engineers plan budgets and choose the optimal production path.

Common PCBA Failures and How to Avoid Them?

Some typical failures include:

- Cold and weak solder joints

- BGA solder voids

- Overheating and thermal runaway

- Signal integrity issues

- Component misalignment

Avoidance begins with:

- DFM review

- Stable soldering processes

- Quality components

- Controlled reflow profiles

- Comprehensive testing

A strong manufacturing partner minimizes these risks.

Why Many Global Customers Trust Best Technology for PCBA Assembly?

Founded in 2006, Best Technology is a global provider specializing in advanced PCB and PCBA solutions. With 19+ years of expertise, we support industries that demand precision, reliability, and fast delivery.

Our PCBA capabilities include:

- Quick turn PCBA assembly

- Prototype PCBA

- Ceramic PCB assembly

- Flex PCB assembly

- Through-hole assembly

- BGA assembly

- Components sourcing

- Box building service

We deliver over 1,000 different boards monthly, backed by strict quality systems, IPC compliance, and engineering support. With facilities in both China and Vietnam, we guarantee stable production, flexible capacity, and fast lead times—even for urgent projects.

If your priority is product reliability, transparent communication, and long-term cooperation, Best Technology is ready to support your next innovation.

How We Ensure Highest Quality of PCBA Product?

As one of a leading PCBA assembly provider, we use strict verification methods guided by global standards to ensure reliability:

- IPC-A-610 acceptance standards

- AOI (Automated Optical Inspection)

- X-ray BGA verification

- Functional testing & ICT

- Thermal cycling & stress tests

These processes prevent issues before boards reach customers, protecting product reputation and reducing field failures.

PCBA Applications We Served

Our PCBA products are across a widely applications, each including:

- Consumer electronics

- Automotive ECUs and battery systems

- Industrial control panels

- Medical diagnostic equipment

- 5G and telecommunications

- Aerospace avionics

- Solar and energy storage systems

- IoT smart home devices

What Industry Certifications We Have?

To offer a better services to our customers, Best Technology passed numerous industry certifications to let our customers no quality worries, our certifications including:

- UL

- ROHS & Reach

- ISO9001 (quality control system)

- ISO14001

- IATF16949 (automotives)

- AS9100D (aerospace & defense)

- ISO13485 (for medical devices)

If you are searching for a reliable PCBA manufacturer, you can welcome to contact us, Best Technology is dedicated to be one of your trusted PCBA supplier both in China and Vietnam. Contat us right now to get your PCBA quotation!

FAQs About PCBA

Q1: What is the difference between PCB and PCBA?

PCB is a bare board; PCBA is fully assembled and functional.

Q2: How long does PCBA production take?

Prototype can be completed within days; complex mass production takes longer.

Q3: How to ensure PCBA quality?

Certified factories, IPC standards, and structured testing.

Q4: What files are needed?

Gerber, BOM, pick-and-place file, assembly drawings, test requirements.

Q5: Can PCBA be customized?

Yes. Custom PCBA supports unique layouts and functions.

language

language