- +84-827-237566

- sales@bestpcb.vn

One-stop PCBA service from electronic component sourcing, rapid prototyping, PCBA manufacturing to box assembly, testing and shipment. RoHS, UL and ISO certified. Made in Vietnam, 24/7 online service, free technical support

Providing one-stop EMS services and vertically integrated solutions to turn your ideas into reality

Quote Now

Provide PCB prototypes/low volume production, can customize special substrates or materials.

Our purchasing team is dedicated to providing components, with a perfect and stable supply chain, aiming to bring you the cheapest price.

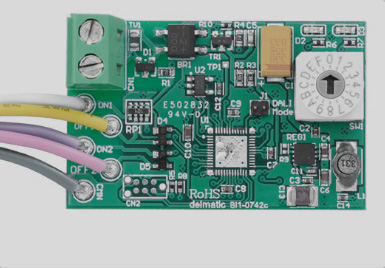

Naisi provides high-precision PCB assembly services, with more than 10 high-speed SMT assembly lines and daily capacity up to 10 million points

Over 19 years experience, using A+ grade materials, fully automatic assembly and 100% full inspection before delivery.

Stable supply chain for all electronic components, SMD, BGA, QFN, QFP..

Mold structure, thread insert, pad printing, laser engraving, final assembly.

CNC Milling, CNC Turning for tighter tolerances, competitive pricing and anodizing options.

Less material waste, flexible material selection, multiple finishing options and cost savings.

24-hour turnkey PCBA solution provider with good quality and fast delivery. Our cases include but not limited to

Check whether the raw materials, such as electronic components, are the same as the BOM list provided by the customer, ensure the raw materials meet the customer's requirement.

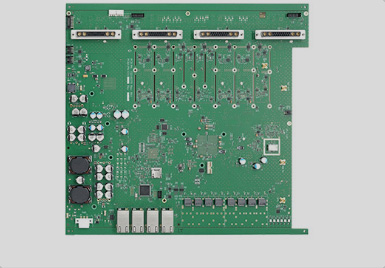

We offer customized raw materials to meet your specific requirements and can manufacture PCBs up to 50 layers. All our processes strictly adhere to IPC standards and fully comply with the ISO9001 quality management system.

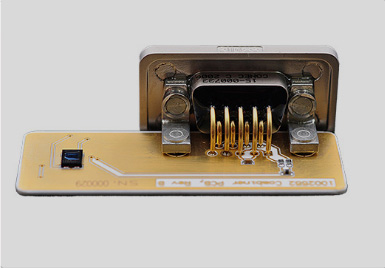

Ceramic PCB and ceramic PCB assembly are one of our specialized services. As one of the leading ceramic PCB manufacturers in Vietnam, we provide a wide range of advanced technologies, including thick film, thin film, DPC, DBC, etc.

Founded on June 28, 2006, Best Technology is committed to providing one-stop PCB solutions to drive technological advancement and innovation. With over 19 years of experience, we have become a trusted partner for clients worldwide, offering best solutions to meet the growing needs of the electronics industry.

Our products range from standard FR4 PCB, multi-layer PCBs, metal-based PCBs (MCPCBs), ceramic PCBs, flexible and rigid-flexible PCBs to high frequency PCBs. Currently our monthly capability is 260,000 square feet (28,900 square meter), more than 1,000 different boards will be completed. We also provide expedite service, so that urgent boards can be shipped out within 24 hours.

As a custom printed circuit board manufacturer, we believe that continuous growth is the key to success. So, we always invest heavily in research and development to stay ahead of industry trends. We focus on product quality and customer satisfaction, and we aim to build strong relationships and offer personalized support and solutions to our customers.

With 18 years of experience in PCB manufacturing and assembly, we offer competitive factory prices and short lead times to ensure your schedule runs smoothly.

We are committed to providing high-quality PCB solutions at competitive prices. By optimizing manufacturing processes and managing costs effectively, we ensure you receive the best value for your investment.

At Best Technology, quality is our top priority. We implement rigorous quality control processes throughout every stage of production, from raw material selection and prototyping to final product testing.

Our all-in-one approach simplifies the supply chain, shortens lead times, and improves communication efficiency. And we offer one-on-one sales assistant services to give you a superior experience working with us.

We understand the importance of meeting your project deadlines, and we provide online WIP updates to ensure you can track the progress of your PCB product.

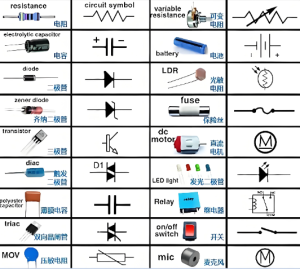

Designing a printed circuit board (PCB) begins long before traces and copper layers are drawn. The first and most important step in any electronic design is creating the schematic drawing — a graphical representation of how electronic components are connected and how signals flow within a circuit. This schematic is the blueprint for the PCB layout, manufacturing, and assembly processes. Understanding its file types, structure, and role in the design workflow is essential for engineers, technicians, and electronics manufacturers. What..

READ MORE »

When it comes to assembling printed circuit boards, engineers often face a big question: Are through-hole components better than SMT components? The answer isn’t as simple as “yes” or “no.” Each technology has its own unique strengths that fit different applications and environments. Let’s explore both technologies in detail to help you make the right choice. What Is Surface Mount Technology (SMT)? Surface Mount Technology (SMT) represents the modern standard in PCB assembly. Instead of drilling holes, components—called Surface Mount..

READ MORE »

When preparing a printed circuit board (PCB) for assembly, one of the most critical steps is providing the manufacturer with accurate and complete documentation. Each file you submit serves a specific purpose, helping engineers and assemblers fabricate, populate, and test your circuit board correctly. Missing or incomplete files can lead to costly delays, incorrect builds, or even total assembly failure. This article explains in detail what files are needed for PCB assembly, why each file matters, and answers some of..

READ MORE »Simply drop your email or phone number in the contact form, and we'll promptly provide you with a quotation.