Best PCBA Manufacturer in China, Fast Delivery

Finding the best PCBA manufacturer in China is a top priority for businesses worldwide, as China has long been a global hub for reliable and cost-effective PCBA manufacturing solutions. Securing the right best PCBA manufacturer is critical to guaranteeing product quality, on-time delivery, and long-term operational efficiency. With 20 years of industry expertise, we know that a standout best PCBA manufacturer must strike a balance between technical proficiency, strict quality control, and customer-focused services. This guide unpacks top manufacturers, industry pain points, our competitive strengths, and practical insights to support your informed decision-making.

Top 10 Best PCBA Manufacturers in China

| Company Name | Core Business | Process Capability | Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | HDI, thick copper, rigid-flex, and buried-resistance PCBA for automotive, industrial, and consumer electronics | 1-32 layer PCBA, 3/3mil min. line width/space, laser drilling, LDI exposure, 100% AOI/ICT testing | 24h rapid prototyping, 5-7 days batch delivery, 98% on-time delivery rate |

| Universal Scientific Industrial (Shanghai) Co., Ltd. | Consumer electronics, communication equipment, and automotive PCBA assembly | Multi-layer PCBA, SMT/DIP assembly, precision soldering, functional testing | 3-5 days prototype, 7-12 days mass production, 97.5% on-time delivery rate |

| Shennan Circuits Co., Ltd. | High-end communication, aerospace, and medical PCBA manufacturing | 1-24 layer HDI PCBA, high-frequency material processing, strict reliability testing | 4-6 days prototype, 8-15 days mass production, 98.8% on-time delivery rate |

| Han’s Laser Technology Industry Group Co., Ltd. | Industrial control, automotive electronics, and smart device PCBA solutions | Laser processing, SMT assembly, multi-process integration, 3D X-ray inspection | 2-4 days prototype, 6-10 days mass production, 97% on-time delivery rate |

| Wingtech Technology Co., Ltd. | Semiconductor integration, consumer electronics, and IoT PCBA assembly | System-level PCBA, BGA rework, high-density assembly, reliability verification | 3-5 days prototype, 7-14 days mass production, 96.8% on-time delivery rate |

| Kaifa Technology Co., Ltd. | Consumer electronics, storage devices, and industrial PCBA manufacturing | 1-16 layer PCBA, SMT/DIP hybrid assembly, environmental testing | 4-7 days prototype, 8-12 days mass production, 98.2% on-time delivery rate |

| Guanghong Technology Co., Ltd. | Consumer electronics, automotive, and medical device PCBA services | Precision SMT, conformal coating, functional testing, batch full inspection | 2-3 days prototype, 5-8 days mass production, 97.8% on-time delivery rate |

| Emdoor Information Technology Co., Ltd. | IoT devices, industrial tablets, and smart hardware PCBA assembly | Customized PCBA, low-volume high-mix production, rapid iteration support | 24-48h prototype, 6-9 days mass production, 96.5% on-time delivery rate |

| Cambridge Technology Co., Ltd. | Communication equipment, optical modules, and network device PCBA | High-speed signal PCBA, optical-electrical integration, strict EMI control | 3-6 days prototype, 7-13 days mass production, 98% on-time delivery rate |

| Zhongjing Electronics Co., Ltd. | Automotive electronics, industrial control, and consumer PCBA manufacturing | Thick copper PCBA, high-temperature resistant processing, batch stability control | 4-5 days prototype, 8-10 days mass production, 97.2% on-time delivery rate |

Pain Points of PCBA Manufacturer in China

- Cost control difficulties, especially for small-batch orders with high engineering and material costs.

- Prolonged prototyping cycles, failing to meet rapid product iteration needs.

- Unstable delivery schedules due to supply chain disruptions and production bottlenecks.

- Inconsistent product quality caused by inadequate process control and inspection standards.

- Technical barriers in complex processes like rigid-flex PCBA and fine-pitch BGA assembly.

- Compliance risks with international certifications for medical, automotive, and aerospace industy.

- Lack of professional DFM analysis leading to design flaws and rework losses.

- High defect rates in mass production, increasing overall manufacturing costs.

Why Choose EBest Circuit (Best Technology) for Best PCBA Manufacturer?

Reasons Why Choose EBest Circuit( Best Technology) for Best PCBA Manufacturer in China:

- Cost competitiveness supported by 19 years of industry experience, we provide cost-sensitive solutions tailored to your design, reducing overall manufacturing costs by 15-20% on average.

- 24-hour rapid prototyping service for urgent orders, accelerating your product launch cycle significantly compared to industry average lead times.

- 99.2% order on-time delivery rate, guaranteed by mature supply chain management and smart production scheduling systems.

- Strict quality control with 100% full inspection for batch orders, combining AOI, ICT, and FCT testing to keep defect rates below 0.05%.

- Advanced process capability covering rigid-flex PCBA, fine-pitch BGA, and 32-layer HDI, overcoming complex manufacturing challenges.

- Full compliance with international certifications including ISO9001:2015, ISO13485:2016, IATF16949, REACH, and RoHS, eliminating certification risks.

- Free professional DFM analysis before production, identifying design flaws in advance to avoid rework and reduce costs.

- Customized quality control plans for different industries, ensuring stable product performance and meeting industry-specific requirements.

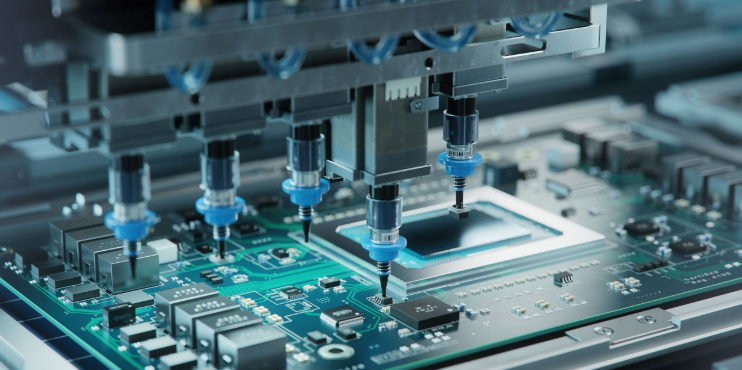

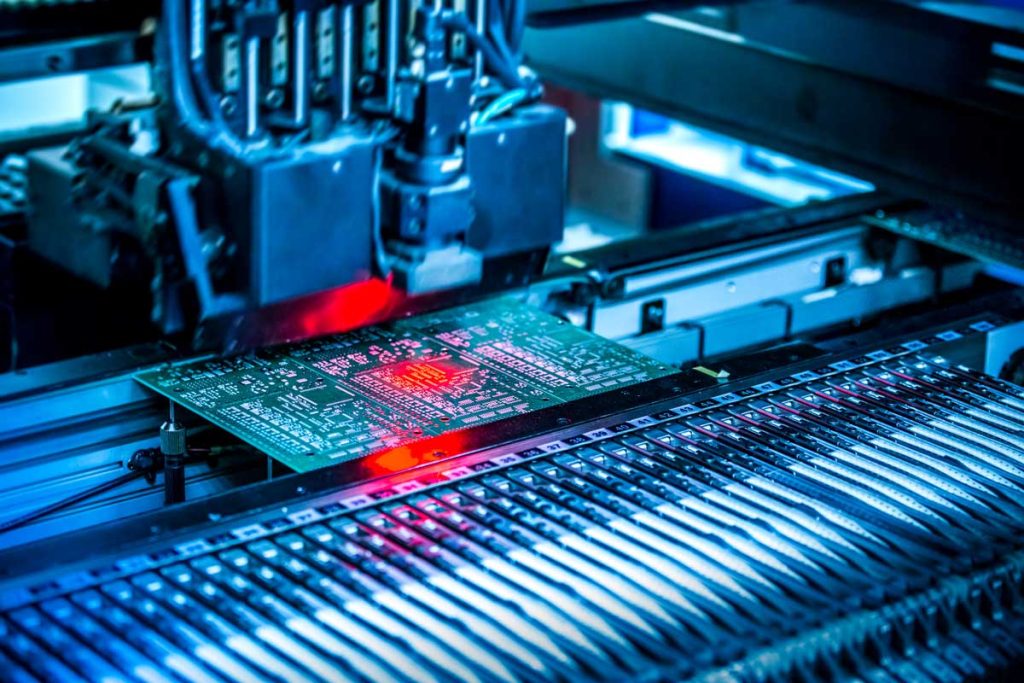

Types of PCB Assembly Service We Offered

As a professional PCBA manufacturer in China, EBest Circuit( Best Technology) can offer you the following options for PCB assembly:

- Surface Mount Technology (SMT): Ideal for high-density, miniaturized components. Enables automated mass production with high assembly density, suitable for compact electronic devices.

- Through-Hole Technology (THT): Designed for robust, high-power applications. Features strong mechanical fixation via lead-through soldering, perfect for high-stress interface scenarios.

- Hybrid Assembly: Combines SMT and THT advantages. Balances miniaturization and structural stability, meeting complex product functional requirements.

Our PCB Assembly Capability

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

Our Quality Certifications for PCB Assembly

As a trusted best PCBA manufacturer in China, we hold a complete set of international quality certifications to ensure product reliability and compliance across industries. Our certifications include:

- IATF 16949: Tailored for automotive electronics, this certification enforces strict quality management for automotive supply chains, requiring application of core tools like APQP and FMEA to ensure stable product performance.

- ISO 9001:2015: The foundational general quality management system certification, covering all production and service links to maintain consistent operational efficiency.

- ISO 13485:2016: Specialized for medical devices, it meets strict regulatory requirements for medical PCBA, ensuring compliance with global medical standards like NMPA and EU MDR.

- AS9100D: The global top quality standard for aerospace applications, adding aerospace-specific requirements on risk management and supply chain control beyond ISO 9001.

- REACH & RoHS: Environmental compliance certifications, restricting hazardous substances to meet global environmental protection and market access requirements.

- UL: International safety certification, verifying the safety of PCBA products to avoid potential safety hazards during use.

All certifications are regularly updated and audited to align with the latest international standards, reinforcing our capability as a reliable PCBA manufacturer in China.

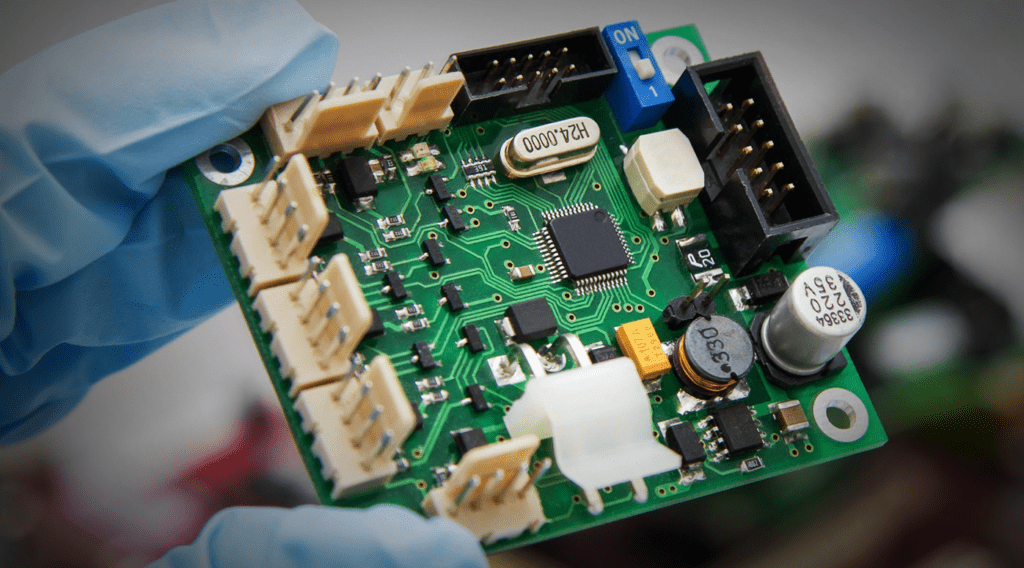

Case Studies of Our Medical PCBA

Project Requirements:

The medical PCBA is a 12-layer rigid-flex board with a size of 35mm×30mm×6mm, requiring 99.8% first pass yield (FPY), 15-20 years of maintenance-free service life, and compliance with ISO 10993 biocompatibility standards.

Challenges:

challenges included ±75μm interlayer alignment accuracy for rigid-flex transition zones, controlling soldering void rate for 0.4mm pitch BGA, and ensuring no flux residue in a Class 10000 cleanroom environment.

Solutions:

We implemented stepped lamination for rigid-flex zones, used laser-mechanical hybrid drilling for precision control, and adopted nitrogen-protected vacuum reflow soldering to reduce void rate below 5%. Free DFM analysis optimized wiring to avoid signal crosstalk, and MES system enabled full-process traceability.

Results:

The project achieved 99.8% FPY, passed 1000 cycles of temperature cycling (-40℃~125℃) testing, and met NMPA and CE MDR requirements. The medical PCBA successfully entered clinical trials, with stable performance in accelerated aging tests simulating 15 years of use.

How to Get A Quote For PCB Assembly Service?

Steps to Get a Quote for PCB Assembly Service:

- Submit Design Files

Upload your Gerber files, BOM (Bill of Materials), and assembly instructions via our email( sales@bestpcb.vn). Ensure files are in standard formats (e.g., .zip, .rar) for quick processing. - Specify Technical Requirements

Outline key parameters such as PCB layer count, material type, minimum trace width, surface finish, and testing standards. Include details on solder mask color and conformal coating if needed. - Choose Turnaround Time

Select your preferred prototype or mass production timeline. Options typically range from 24-hour rapid prototyping to 10–15-day standard mass production. - Contact Our Support Team

Reach out via email or online chat with your project specifications. Our engineers will review your requirements and provide a detailed quote within 2–4 hours. - Review and Confirm

Check the quote for accuracy, including component costs, assembly fees, and shipping options. Confirm acceptance to proceed with production.

Welcome to contact us to get a free quote for your PCBA project: sales@bestpcb.vn.

language

language