Turnkey Electronics Box Build Assembly Service

What is the Box Build Assembly Process?

Electronics box build assembly refers to the complete process of integrating printed circuit board assemblies (PCBAs), wiring harnesses, connectors, and other mechanical and electronic components into a final enclosure. This “box” can be a simple plastic casing or a complex metal housing for industrial or aerospace applications.

The process generally involves:

1. Design Review and Material Procurement – Engineers assess the customer’s mechanical and electrical requirements, then source materials and components according to the bill of materials (BOM).

2. Sub-Assembly Integration – PCBs, cable assemblies, power supplies, and other parts are assembled and tested individually.

3. Final Assembly – The sub-assemblies are installed into enclosures, wired, and secured to meet design specifications.

4. Functional Testing and Inspection – Every completed unit undergoes functional and visual inspections to verify performance, safety, and reliability.

5. Packaging and Delivery – The fully built system is labeled, packaged, and shipped according to customer requirements.

This end-to-end process ensures that the customer receives a turnkey solution, ready for immediate use or distribution.

How to Assemble Electronic Components in a Box Build?

The assembly of electronic components in a box build follows a systematic approach to maintain product integrity and efficiency. Here’s how professional box build assembly manufacturers like Best Technology perform it:

- Component Preparation: Each electronic and mechanical component is verified and prepared for assembly.

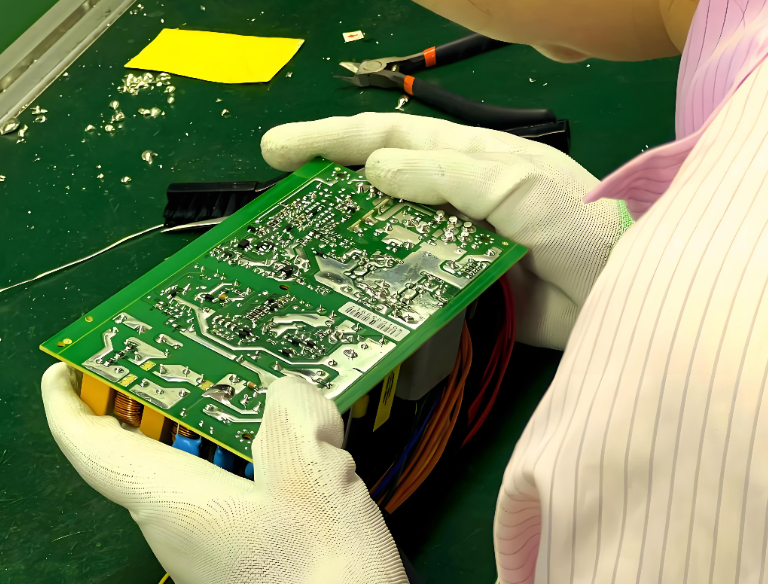

- PCB Integration: The completed PCBA is mounted securely inside the enclosure using precision fixtures.

- Cable and Wire Harness Installation: Internal wiring and harnesses are connected according to the schematic diagram.

- Sub-System Connection: Displays, control panels, and interfaces are installed.

- Power Supply Integration: Power modules or battery systems are installed and tested.

- Final Functional Testing: Engineers ensure all electronic components operate properly within the system.

The process is optimized for consistency, reliability, and high-volume production efficiency.

What is the Difference Between Box Build and PCBA?

Although PCBA (Printed Circuit Board Assembly) and box build assembly are related, they refer to different stages of electronic product manufacturing.

| Category | PCBA (Printed Circuit Board Assembly) | Box Build Assembly |

| Definition | Process of soldering electronic components onto a bare printed circuit board (PCB) to create a functioning electronic circuit. | Complete system integration that includes PCBAs, wiring, mechanical components, and enclosures to create a finished product. |

| Manufacturing Stage | Mid-stage manufacturing (focus on the electronic circuit). | Final stage of manufacturing (focus on full product assembly). |

| Core Processes | Solder paste printing, SMT placement, reflow soldering, through-hole soldering, AOI testing, ICT testing. | Enclosure assembly, cable harness installation, sub-assembly integration, labeling, and final functional testing. |

| Main Components Involved | Bare PCB, resistors, capacitors, ICs, transistors, connectors, etc. | PCBA, cables, power supplies, switches, displays, fans, housing, screws, and mechanical hardware. |

| Engineering Focus | Electrical design and functionality. | System design, mechanical layout, and final product usability. |

| Design Files Required | Gerber files, pick & place files, BOM (Bill of Materials). | Assembly drawings, wiring diagrams, mechanical layout, labeling and packaging instructions. |

| Testing Level | AOI (Automated Optical Inspection), ICT (In-Circuit Testing), and functional test at board level. | Complete system-level testing including power-on, vibration, burn-in, and environmental tests. |

| Output Product | Functional circuit board, ready for integration. | Fully assembled electronic device or subsystem, ready for shipment or deployment. |

| Lead Time | Shorter, as it involves fewer components and assembly steps. | Longer, as it includes PCBA plus mechanical and system integration. |

| Quality Standards | IPC-A-610, ISO 9001. | IPC-610, IPC-620, ISO 9001, and sometimes AS9100D (for aerospace and defense). |

| Production Volume | Typically high-volume mass production. | Often lower or medium volume, depending on complexity. |

| Assembly Skills Required | Electronic soldering, SMT/THT operations, component handling. | Mechanical fitting, cabling, wiring, assembly integration, and system testing. |

| End Users | Usually delivered to OEMs for further product assembly. | Delivered to end customers or distributors as a complete, ready-to-use product. |

| Example Products | Motherboards, power modules, control boards. | Routers, industrial control boxes, medical devices, or communication systems. |

Benefits of Electronics Box Build Assembly

- One-Stop Manufacturing Solution: Eliminates the need to manage multiple suppliers — from PCB assembly to enclosure integration.

- Reduced Lead Time: Streamlined processes improve production efficiency and delivery speed.

- Quality and Reliability: Controlled environments, skilled technicians, and advanced testing ensure consistent performance.

- Cost Efficiency: Reduced logistics, lower overhead, and minimized handling errors.

- Scalability: Easy to scale production based on demand — ideal for startups and OEMs.

- Expert Support: Engineering teams provide DFM (Design for Manufacturability) and DFT (Design for Testability) recommendations.

Why Choose Best Technology Circuit for Your Box Build Assembly Needs?

When it comes to electronics box build assembly, selecting a reliable and experienced manufacturing partner is critical to ensuring your products meet high-quality, functional, and delivery standards. Best Technology Circuit stands out among box build assembly manufacturers for our end-to-end capability, precision engineering, and commitment to quality.

- We handle every step: component sourcing, PCBA, wiring, enclosure assembly, labeling, and final packaging.

- Support for both prototype development and mass production projects.

- Provide DFM (Design for Manufacturability) and DFT (Design for Testability) advice.

- IPC-A-610 and IPC/WHMA-A-620 trained technicians

- We support turnkey, partial turnkey, and consigned assembly options depending on your supply chain preference.

- Perform functional, in-circuit, and burn-in tests

- Clear documentation and process control from prototype to shipment.

- Custom labeling, barcoding, and serialization.

- ESD-safe packaging and protective shipping solutions.

- Drop shipping and logistics coordination for global customers.

Choosing Best Technology Circuit means choosing a partner with full turnkey capability, engineering depth, and a proven quality record. From concept design to final product delivery, we ensure your electronics box build assembly is reliable, compliant, and ready for market success. Welcome to contact us if you are interested in electronics box building assembly service.

FAQs

1. What industries use box build assembly services?

With over 18 years of experience, Best Technology serves diverse industries including:

- Aerospace & defense

- Medical devices

- Industrial automation

- Telecommunications & IoT

- Consumer electronics

- Industrial control

2. Can I provide my own components for box build assembly?

Yes. Best Technology supports both full turnkey (we supply everything) and consigned (you provide components) assembly options.

3. What information is needed for a box build quotation?

You should provide the bill of materials (BOM), assembly drawings, wiring diagrams, enclosure details, and testing requirements.

language

language