Are through-hole components better than SMT components?

When it comes to assembling printed circuit boards, engineers often face a big question: Are through-hole components better than SMT components? The answer isn’t as simple as “yes” or “no.” Each technology has its own unique strengths that fit different applications and environments. Let’s explore both technologies in detail to help you make the right choice.

What Is Surface Mount Technology (SMT)?

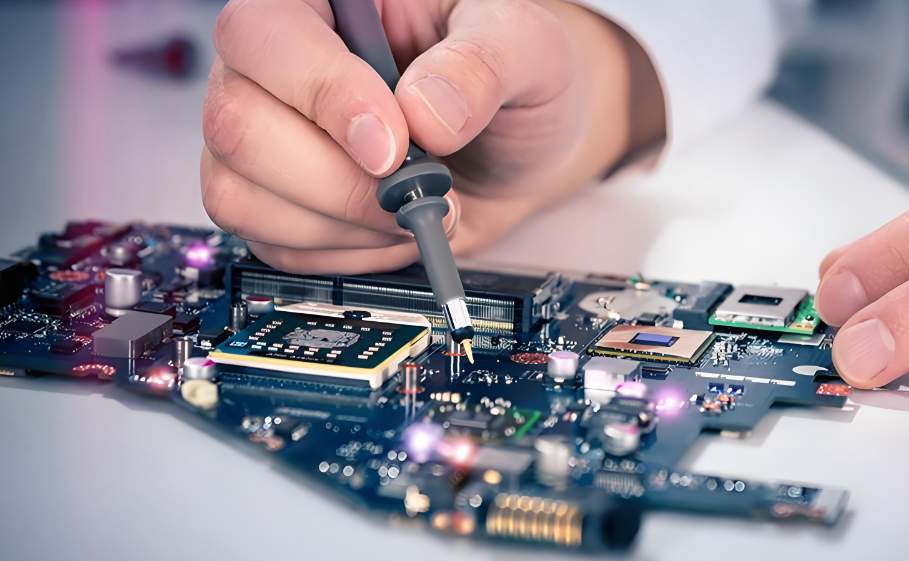

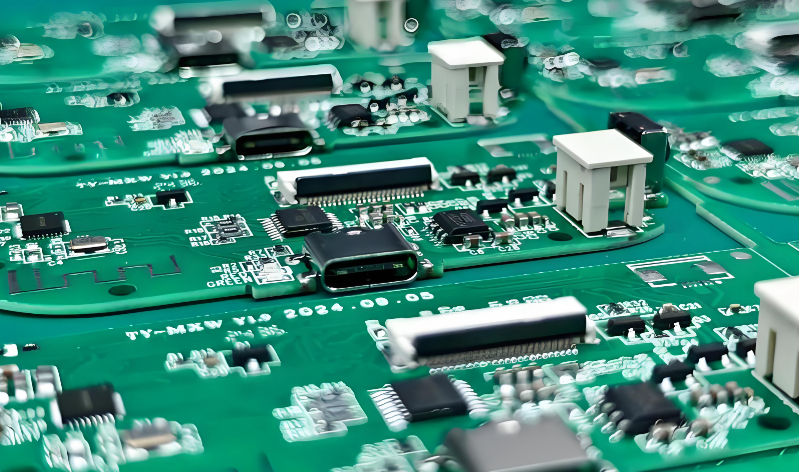

Surface Mount Technology (SMT) represents the modern standard in PCB assembly. Instead of drilling holes, components—called Surface Mount Devices (SMDs)—are placed directly onto the board’s surface.

This is done using automated pick-and-place machines that position each component precisely on pads coated with solder paste. The board then passes through a reflow oven, where the paste melts and forms permanent electrical joints.

The result is a smaller, lighter, and more efficient board. SMT components have no leads or very short leads, which reduces parasitic inductance and resistance—important for high-frequency and high-speed circuits.

SMT brings several major advantages:

- Compact size: Allows for dense circuit layouts and miniaturized devices.

- Automation-friendly: Enables high-volume production at lower cost.

- Better performance: Shorter signal paths reduce noise and improve reliability.

- Two-sided assembly: Components can be mounted on both sides of the PCB.

Because of these advantages, surface mount technology dominates consumer electronics, telecommunications, and medical equipment manufacturing. Products like smartphones, tablets, laptops, and IoT devices all rely heavily on SMT.

What Is Through-Hole Technology?

Through-hole technology is one of the oldest PCB assembly methods, developed in the mid-20th century. In this process, component leads are inserted into drilled holes on the PCB and soldered on the other side, forming strong electrical and mechanical connections.

The defining feature of THT is the use of plated through-holes (PTHs). These holes are drilled through the board and plated with conductive material to connect layers. The component leads are pushed through these holes and soldered, either manually or by wave soldering.

Because the component leads physically pass through the board, they withstand mechanical stress far better than surface-mounted parts. That’s why through-hole technology is still widely used in:

- Aerospace and defense electronics

- Industrial control systems

- Automotive power modules

- Heavy-duty machinery and energy systems

In these sectors, strength and reliability are more important than size or weight. A properly soldered THT joint can handle vibration, heat, and stress far better than a small SMT pad.

Difference Between SMT and Through-Hole Technology

When comparing SMT vs THT, the differences go far beyond the way components are attached. They influence everything—from mechanical stability and manufacturing cost to design flexibility and final performance. Here’s a detailed comparison:

| Aspect | Through-Hole Technology (THT) | Surface Mount Technology (SMT) |

| Mounting Method | Component leads pass through drilled holes and are soldered on the opposite side | Components are mounted directly onto the PCB surface |

| Connection Type | Mechanical and electrical connection through holes | Electrical connection through solder pads only |

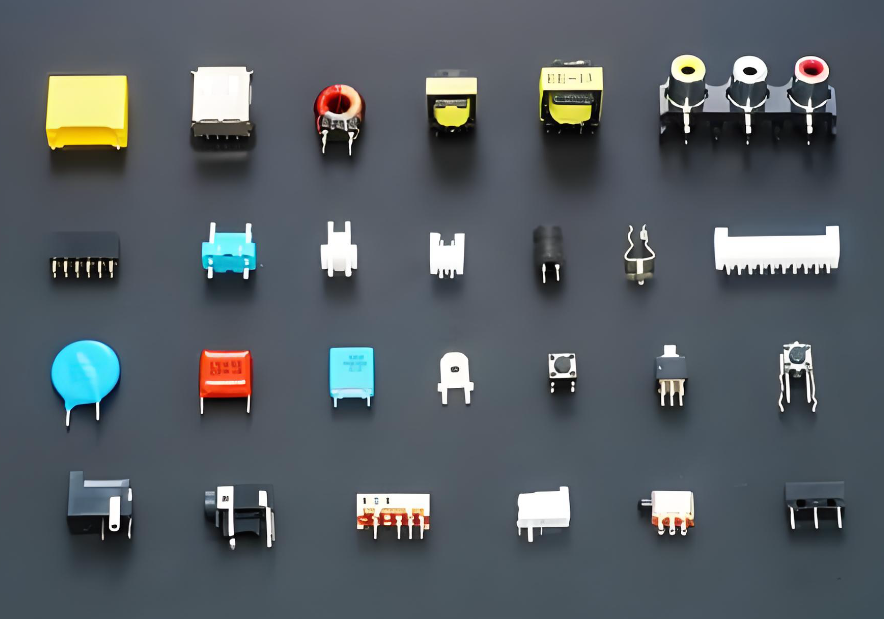

| Component Size | Larger, traditional components with visible leads | Miniature components designed for compact layouts |

| Assembly Method | Manual or wave soldering | Automated pick-and-place and reflow soldering |

| Design Density | Limited by drilling and component spacing | Allows high-density, multi-layer circuit designs |

| Mechanical Strength | Excellent resistance to vibration and stress | Moderate; not ideal for heavy mechanical load |

| Repair & Testing | Easier to test, replace, or modify manually | More difficult to repair due to small component size |

| Cost Efficiency | Higher labor and drilling costs | Lower production cost in mass manufacturing |

| Typical Applications | Aerospace, automotive, industrial electronics | Consumer electronics, communication, medical devices |

In short, THT provides strength and reliability, while SMT offers miniaturization and scalability.

Through-Hole vs SMD: Which One Performs Better?

When comparing through-hole vs SMD components, it’s essential to focus on performance context. SMD (Surface Mount Device) components generally perform better in speed, miniaturization, and automation, whereas through-hole components excel in strength and long-term reliability.

For instance, power connectors, transformers, and large capacitors are still often built with THT due to their mechanical stability. Meanwhile, microcontrollers, ICs, and resistors use SMT because they’re easier to assemble and take up less space.

So, performance depends on the project’s purpose:

- If your device faces heavy vibration or mechanical stress—choose THT.

- If you’re designing compact, high-speed electronics—SMT is the better option.

When Should You Choose Through-Hole Technology (THT)?

While many modern designs lean toward SMT, through-hole technology remains crucial for specific applications. Choose THT when your design requires:

- Strong physical connections for components under mechanical load.

- Reliable solder joints for high-temperature or high-voltage operations.

- Prototyping flexibility, as THT components are easier to handle and test.

These advantages explain why many aerospace, automotive, and military PCB assemblies still rely on through-hole soldering to achieve maximum durability.

When Should You Choose Surface Mount Technology (SMT)?

Surface mount technology suits most of today’s electronics production. Choose SMT when your project demands:

- Miniaturization and light weight, perfect for portable or wearable devices.

- Mass production, as SMT supports full automation and high-speed assembly.

- Cost efficiency, reducing drilling and manual work.

- High-frequency performance, since SMT traces are shorter and more efficient.

In essence, SMT meets the growing demand for compact, fast, and cost-effective electronics, from smartphones to medical instruments.

SMT vs THT: Can They Be Used Together?

Yes, many PCB designs use both SMT and THT components to balance performance and cost. This hybrid approach is common in mixed-technology boards, where surface-mounted ICs coexist with through-hole connectors or transformers.

Manufacturers often perform SMT assembly first, followed by wave soldering for through-hole parts. This combination optimizes both electrical performance and mechanical reliability.

How to Decide Between Through-Hole and SMT Components?

Choosing between SMT and THT depends on your priorities:

- For compact design and mass production: SMT is preferred.

- For mechanical robustness and durability: THT is better.

- For mixed performance: Hybrid assembly gives the best of both worlds.

Evaluating cost, reliability, and space constraints early in the design phase helps ensure the right balance between performance and manufacturability.

Why Partner with Best Technology for SMT and THT PCB Assembly?

In many cases, combining both leads to optimal performance. With Best Technology’s professional PCB manufacturing and assembly services, you can leverage the advantages of both to create dependable, high-quality products that meet every design challenge.

At Best Technology, we provide both SMT and through-hole assembly services tailored to diverse industries, including automotive, aerospace, and medical electronics. With our skilled engineering team, we support complex mixed-technology boards, from prototype to mass production. Whether your project needs surface mount technology, through-hole soldering, or hybrid assembly, Best Technology guarantees precision, reliability, and timely delivery.

Our expert engineers handle mixed-technology boards, offering:

- High-speed automated SMT assembly

- Precision through-hole soldering (manual & wave)

- Rapid prototyping and full-scale production

- Quality inspection using AOI, X-ray, and ICT systems

Whether you need surface mount technology, through-hole assembly, or a hybrid solution, Best Technology ensures accuracy, reliability, and on-time delivery for every PCB project.

language

language