- +84-827-237566

- sales@bestpcb.vn

Naisi is committed to providing sample/small batch PCB manufacturing services to more than 200 countries and regions.

We offer a wide range of high-quality raw materials to meet our customers' diverse customized needs.

Thermal conductivity: 24W/mK, provides 96% Al2O3, 99.6% Al2O3, high mechanical strength, high electrical insulation, good light resistance and corrosion resistance.

High thermal conductivity up to 320 W/mk, low dielectric loss, and low coefficient of thermal expansion.

Rogers substrates have low dielectric constants and low tangent losses, making them suitable for high-speed, high-frequency signal transmission. For example, the Rogers RT/duroid 5870 has a dielectric constant of 2.33 and tangent losses of 0.0009 at 10 GHz.

The entire 1xxx, 2xxx, 3xxx, 4xxx, 5xxx, and 6xxx series, with a thermal conductivity of approximately 237 W/mk when manufactured into aluminum PCBs, can effectively solve the heat dissipation problem of electronic devices.

With a thermal conductivity of 401W/mk (when using sinkPad technology), it possesses excellent thermal conductivity, allowing for rapid heat transfer to the heatsink or cooling fan, making it suitable for cooling high-power electronic devices.

Polyimide has extremely high heat resistance; its decomposition temperature can reach 500°C to 600°C, making it one of the most stable polymers at this stage. It can withstand temperatures from -200°C to 300°C for long-term use.

We source all parts directly from the manufacturer or from authorized distributors such as Digikey, Mouser, Future, TTI, Avnet and Arrow to avoid counterfeit parts.

We also stock a large inventory of common parts. If we can't find a specific part, our engineers will make suggestions for affordable alternatives.

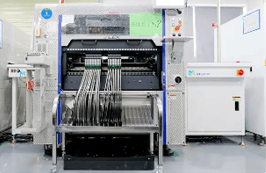

Get free consultation| Item | Ability |

|---|---|

| Mounting Speed | 13,200,000 chips/day |

| Panel Dimension | 0.2 x 0.2 inches - 20 x 20 inches/ 22*47.5 inches |

| Min. SMD Components | 01005 |

| Min. BGA Pitch | 0.25mm |

| Max. PCB Dimension | L50*50mm-L510*460mm |

| Assembly Type | SMT, THT, Mixed assembly, Wire harness |

| Components Package | Roll, cut tape, tubes, trays, separate parts |

| Lead Time | 1-5 days |

Using modern equipment to help you have faster assembly times, higher accuracy and lower costs

With 18 years of experience in PCB manufacturing and assembly, we offer competitive factory prices and short lead times to ensure your schedule runs smoothly.

We are committed to providing high-quality PCB solutions at competitive prices. By optimizing manufacturing processes and managing costs effectively, we ensure you receive the best value for your investment.

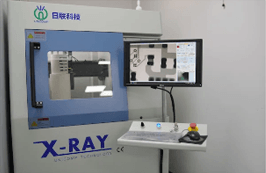

At Best Technology, quality is our top priority. We implement rigorous quality control processes throughout every stage of production, from raw material selection and prototyping to final product testing.

Our all-in-one approach simplifies the supply chain, shortens lead times, and improves communication efficiency. And we offer one-on-one sales assistant services to give you a superior experience working with us.

We understand the importance of meeting your project deadlines, and we provide online WIP updates to ensure you can track the progress of your PCB product.

Small-batch costs spike due to individual component sourcing and setup fees. Fix it by using suppliers with shared BOM procurement (combining orders to lower unit costs) or choosing standard components from their in-stock inventory (many top providers stock 300k+ standard parts). Avoid custom materials unless absolutely necessary.

Run a DFM (Design for Manufacturability) check before submitting files—focus on pad sizes, component spacing, and layer stack alignment. Use free DFM tools from reputable suppliers or consult their engineering team for a pre-production review. Double-check polarity markers and through-hole positioning to prevent rework.

Prioritize suppliers offering express turnaround (2-5 days) with in-house assembly. Opt for SMT-only designs (faster than mixed THT/SMT) and provide complete, error-free BOMs with part numbers. Avoid last-minute design changes—lock in your schematic before production starts.

Start with a visual inspection for missing components or solder bridges. Use a multimeter for continuity checks and a simple function generator for basic signal tests. For hidden solder joints (BGA/QFN packages), ask your supplier for X-ray inspection reports—many include this for prototypes at minimal cost.

Prototypes often use non-production-grade materials or shortcuts (e.g., hand soldering). Fix it by using the same materials (FR-4 grade, surface finish) and processes (automated SMT, reflow soldering) as mass production. Include FAI (First Article Inspection) in your prototype order to validate design consistency.

Use suppliers with a global supply chain network—they can source rare parts faster than individual buyers. Ask about "component substitution" options for obsolete parts (ensure substitutes meet your electrical specs). Consider stocking basic components yourself for frequent prototype iterations.

Choose suppliers with documented compliance certificates for materials and processes. Avoid lead-based solder and specify RoHS-compliant components in your BOM. Request a compliance report with your prototype—reputable providers will include this to ensure global market access.

Poor solder quality often stems from incorrect thermal profiles or low-quality solder paste. Work with suppliers using automated template printing and multi-zone reflow ovens (not hand soldering). Request AOI (Automated Optical Inspection) reports to catch issues like voids or insufficient solder early.

Yes—most suppliers accept customer-provided components (CPK). Label each component clearly with part numbers and quantities. Ensure components are stored properly (e.g., moisture-sensitive ICs in sealed packaging) to prevent damage during assembly. Confirm with your supplier upfront about CPK policies to avoid delays.

Validate your design with a functional prototype first (using production-like materials). Test for key performance metrics (voltage, signal flow) before finalizing. Incorporate feedback from DFM reviews—common fixes (adjusting trace width, component placement) eliminate 80% of iteration needs.

Simply drop your email or phone number in the contact form, and we'll promptly provide you with a quotation.